Software, Content Management and Retrieval Systems for IETD

Pragmatic approaches and procedures have convinced us that the necessary IT support based on the principle: "from practical experience, for practical application" is the most efficient solution for our range of services.

This is the reason why we at eko•ILS Logistics GmbH have developed tailor-made solutions over the years for a wide range of applications that reliably support us in rendering our services and ensuriung a high degree of customer satisfaction.

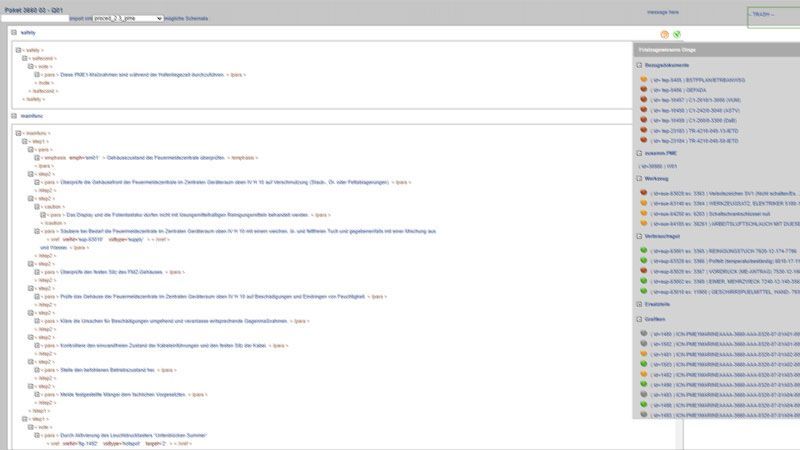

XML-based Editorial System for ASD S1000D

As a service provider with a focus on, among other things, creating and processing IETDs, we at eko•ILS Logistics GmbH inevitably rely on efficient IT support that is appropriate to the task at hand. Having examined the market and tested various software solutions in this environment, we have come to the conclusion that there is, or can be, no one standard application that meets the diverse tasks and requirements of our customers. Consequently, we have drawn on our experience in this area to develop our own content management system for creating and maintaining IETD.

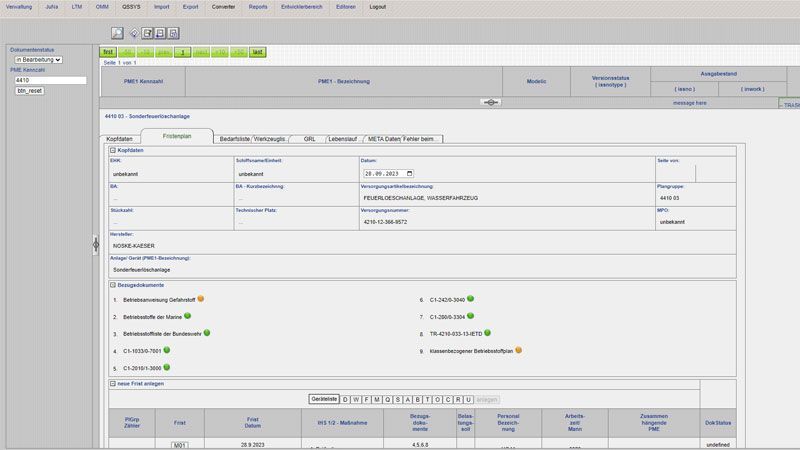

IETD Administration

The entire creation, verification and release process, right up to verification of IETD use, always requires a considerable number of tasks in order to administer the associated metadata. To do this, we have developed two data processing procedures, ECMS (Enterprise-Content-Management-System) and JuNa (Justiziable Nachweisführung, “justiciable verification”), which, among other things, include the following tasks:

- documentation versioning,

- review and approval status,

- release process,

- as well as distribution key and verification.

We have created approximately 2,500 IETDs of the German Naval Forces in this area within the scope of our usage period support.

iWiS© Retrieval System

In 2008, the Naval Project Department of the previously named Federal Office for Defence Technology and Procurement (BWB), today's BAAINBw, decided that the IETD used by the German naval forces would be created exclusively and with immediate effect in accordance with ASD S1000D, version 2.3. Initially planned as a transitional solution until a comprehensive and functionally suitable uniform solution for the Bundeswehr would be available, it was decided at the time to use the iWiS© retrieval component developed by us for the IETD. iWiS© has since been successfully used for more than a decade for all IETD of the German Navy and other documentation from the German Air Force and German Army.

Maintenance Management

As an essential element of maintenance management pursuant to DIN EN 13306, we have developed software to support the corresponding activities related to preventive maintenance, i.e. maintenance that can be planned.

As a component of an integrated logistics solution, it contains the necessary data-related prerequisites, links and functions required for:

- maintenance planning,

- task description,

- required HR and material resources,

- and activity execution verification.

As-build Status Tracking / Logistics Track Management-System

In order to track and process technical changes for their logistical relevance, it is necessary to record these processes in a traceable manner in a computer-aided tool. This is especially true when it comes to integrated plants and systems with links and cross-relationships between their technical ("originator") and logistical ("affected party") factors and products. We at eko•ILS Logistics GmbH have incorporated our long-standing experience in this field into the development of a computing system that efficiently facilitates this kind of processing.

Obsolescence Management

To track and process the tasks to be performed regarding "obsolescence", we have developed a computer-aided procedure that has been application-tested as a facilitating tool in various projects.

We use this tool whenever an order is placed when facilitating the obsolescence management (OM) process in order to:

- identify relevant OM candidates,

- record and evaluate OM messages,

- automatically generate and process required manufacturer queries,

- and present the facts of the case and do reporting.